Monthly Racking Inspection Sheet

This pallet racking inspection checklist is for general guidance and should be used only by trained and qualified racking inspectors.

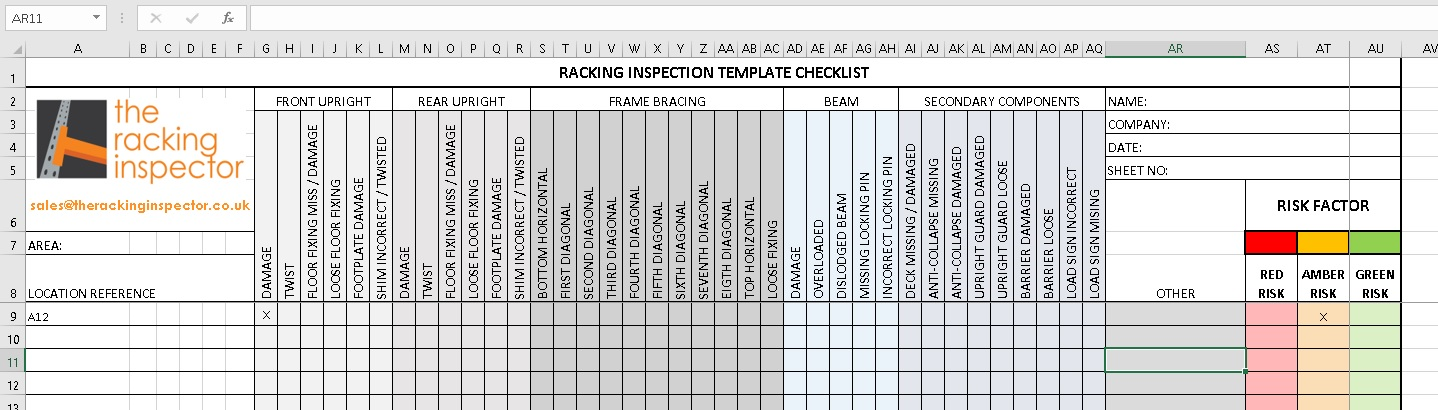

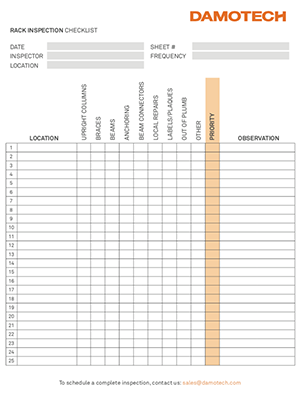

Monthly racking inspection sheet. This checklist does not cover every aspect of pallet racking inspections and it is the responsibility of the person s carrying out the inspection to be aware of. A rack inspection check the storage system for damage. In doing this you are also protecting your staff from injury. A racking inspection checklist is used by authorized warehouse inspectors to identify rack issues or any potential risks of a rack collapsing this tool can be used to assess rack components such as frames beams and braces and determine the level of risks through the traffic light system.

Safety inspections can also improve the feedback loop between worker health and company safety policies. Rack uprights and shelving properly secured fork lift trucks properly maintained and operated. Warehouse inspections are crucial to the prevention of accidents injuries and illnesses. Racking inspections shall be carried out on a regular basis and at least every twelve months.

Because warehouse workers increasingly face problems like increased exposure to repetitive motions and high stress environments checklists are particularly useful in preventing bodily strain related injuries. Inspections of pallet racking should be completed at least once every 12 months by a sema approved inspector and more frequently by internal staff. Warehouse safety inspection checklist campus date building room instructions. Check each item below as satisfactory or unsatisfactory add any pertinent comments and the location of hazards in the space provided for.

Consider racking inspection training for regular internal racking inspections hse guidelines also advise that racking inspections are done regularly by employees within the business itself. With a warehouse audit checklist you can ensure that you don t miss inspections of specific areas because you have a comprehensive list of everything. Regular racking inspections can help prevent serious injuries and fatalities from rack collapses. Pallet rack inspection checklist employers can use this checklist to help ensure their pallet racks are inspected by a qualified person as per the new storage rack requirements of section 4 43 1 of the occupational health and safety regulation effective january 1 2018.

Clearly stated in the australian standards is the need for an annual safety rack inspection. Pallet racking is defined as work equipment meaning that it s the responsibility of you as an employer to ensure it is compliant with current health and safety legislation. Persons responsible for carrying out internal inspections should attend a one day rack safety awareness course to receive the necessary training. The recommended way of ensuring compliance is with an annual racking inspection.

Click here to download your free rack inspection sheet and help your team carry out regular safety checks on your racking.