Motor Lamination Bonding Adhesive

Magna tac e645 is a two part thermosetting formulated epoxy adhesive for bonding stack laminations used in stators rotors gyros servomechanisms synchros transformers and magnetic amplifiers.

Motor lamination bonding adhesive. It is designed for metal to metal coating and subsequent bonding. As motors become smaller and more powerful adhesive bonding gains in popularity and the variety of materials and surfaces it can be used on expands more and more engineers are likely to consider using it for their applications. Commonly used types of adhesives for bonding. As we know all of the motor engineers would like to design the motor with higher efficiency while some efficiency lost can not be avoid such as the iron loss of the stators.

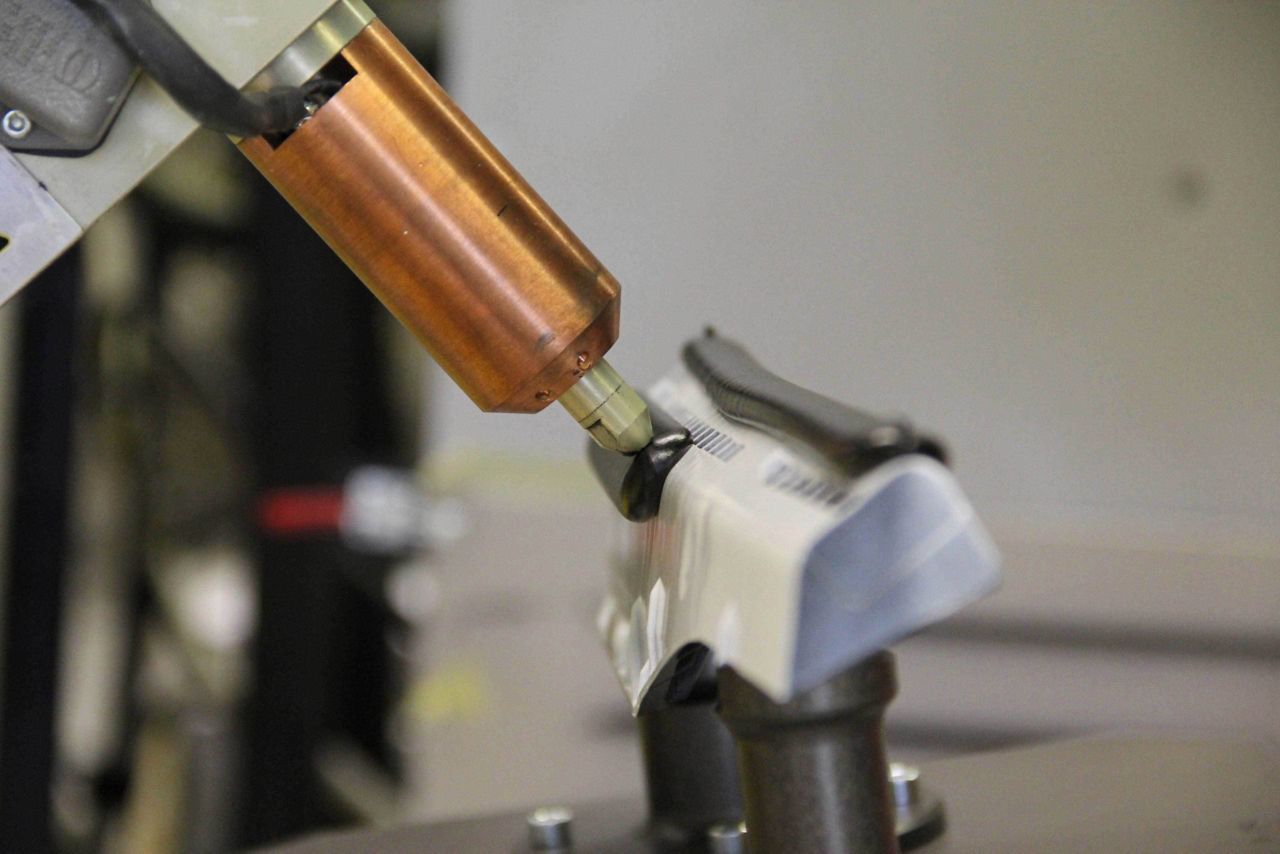

The backlack coating is softened in the first phase by increasing the temperature. After the laminations have been stamped we connect thermally in a two step adhesive bonding process. Lamination bonding with backlack has a wide array of advantages. One and two component epoxy adhesives sealants and potting compounds offer toughness high strength adhesion and cost effective performance in electrical motor and generator assembly applications.

China motor lamination bonding adhesive with high quality leading motor lamination bonding adhesive manufacturers suppliers find motor lamination bonding adhesive factory exporters. Typical applications stator to housing bracket to housing bond. How to do it and what is the advantage of this technology. Motor cutaways dc motor 2 ac motor 4 applications bonding general 6 bonding magnets 8 gasketing 10 potting 12 retaining 14 tacking 16 threadlocking 18.

The viscosity of the coating decreases dramatically making it possible for the coating layers to diffuse and intermix. As an electric motors manufacturer you face demanding market requirements for increased durability lower manufacturing costs and greater motor efficiency. These compounds are designed to provide thermal stability resistance to moisture chemicals vibration impact and thermal cycling. Stator bonding also called glued stators lamination or bonded stator lamination.

For example in motor lamination and wire winding. Table 11on page 26 gives a more complete comparison of all ten adhesive types. Karl bitzer is head of product management at delo industrial adhesives. Not only does our bonding varnish technique leave the highly important magnetic flux undisturbed it applies no stress and does not deform the material ensuring that the magnetic properties remain entirely intact.

.jpg)