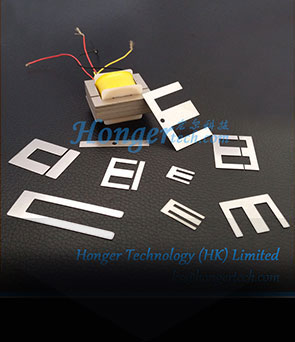

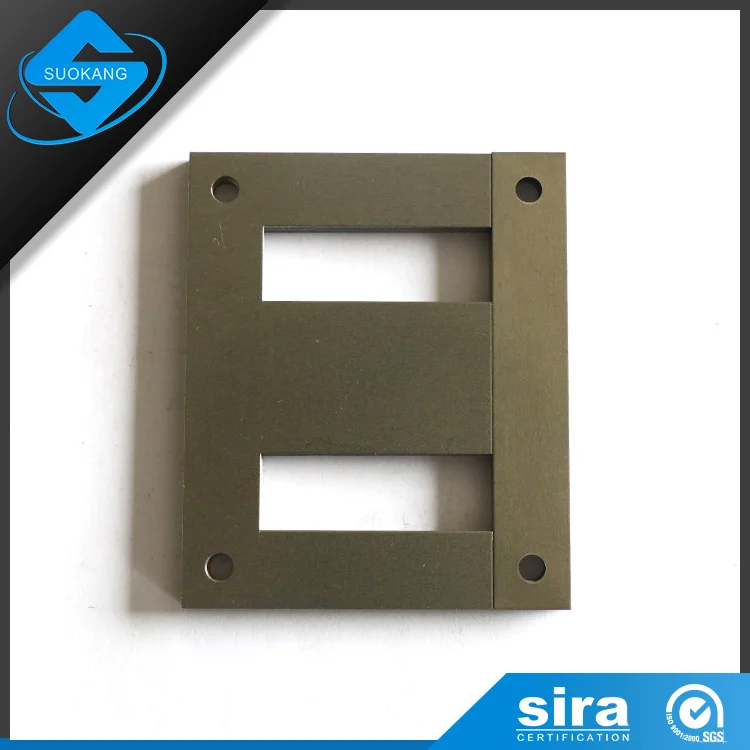

Mu Metal Transformer Laminations

Still by using suitably arranged strips laminations that problem can be avoided.

Mu metal transformer laminations. When i first encountered the lundahl ll1544a and ll1545a line level transformers which use the same coils but these. Mu metal lamination made from nickel iron based alloy also called permalloy. That means that one needs to be careful about the geometry of the core to avoid losing energy to eddy currents. Mu metal has another drawback for use as transformer cores.

Here are his impressions. A magnetic core is a piece of magnetic material with a high magnetic permeability used to confine and guide magnetic fields in electrical electromechanical and magnetic devices such as electromagnets transformers electric motors generators inductors magnetic recording heads and magnetic assemblies it is made of ferromagnetic metal such as iron or ferrimagnetic compounds such as ferrites. Pml has established a new division called hi perm. With high cost effective character now it s the mainly part of high end audio transformer sensor and other sensitive application.

These alloys are used for various applications such as magnetic shielding transformer cores etc. With high cost effective character now it s the mainly part of high end audio transformer sensor and other sensitive application. Mu metal lamination made from nickel based alloy also called permalloy. High permeability products mainly consist of nickel and iron alloys including mu metals.

Mu metal lamination made from nickel based alloy also called permalloy. Ui type mu metal lamination core for transformer mu metal lamination made from nickel iron based alloy also called permalloy. With high cost effective character now it s the mainly part of high end audio transformer sensor and other sensitive application. It is electrically conducting.