Music Wire Spring Heat Treatment

Music wire is patented and cold drawn to size.

Music wire spring heat treatment. Stainless steel coils will generally expand slightly when heated. Spring wire heat treatment. It is recommended for small helical and torsion springs. Music wire coils will generally contract slightly.

It has the highest tensile strength and can withstand higher stresses under repeated loading than any other spring material. They are ready to use as is. Then press the ends against a red hot steel plate. It s often used to make springs and wire rope.

Heat treating music wire by roy vaillancourt. Low temperature heat treatment 260 to 290 c of music wire after coiling relieves stresses within the wire due to cold work performed in coiling. Definition of heat treating springs. I never do any heat treating of music wire springs i wind.

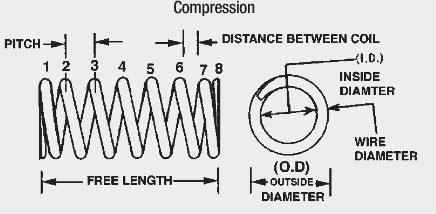

If the spring will set solid compress all the way so that all the coils touch each other at the limit of its travel the diameter of the wire times the number of coils. Use it in a variety of marine and chemical processing applications. Music wire is cold drawn and it has a high and uniform tensile. You want the end of the spring to get hot and soft enough to flatten but pull it away from the hot plate as.

If you want a flat end on a compression spring cut it a bit longer than the desired final length. Music wire is the toughest and most widely used of all spring materials for small springs. The addition of molybdenum gives 316 stainless steel excellent corrosion resistance. On this scale rc20 is soft rc45 is.

Wire springs are placed in an oven or furnace for a certain time and temperature to relieve stress as well as to temper the spring wire to give the spring its elasticity and memory. This is a general purpose commercial quality class ii tensile spring steel wire to astm a 229. With a quality between hard drawn spring wire and music wire moderately priced otmb is excellent for springs without severe bends. Equivalent or common trade names.

On this scale rc20 is soft rc45 is tough and rc60 is hard. The material is cold drawn to the desired size and heat treated by a continuous tempering method. Acxess spring s heat treating chart.