Natural Gas Containment Systems

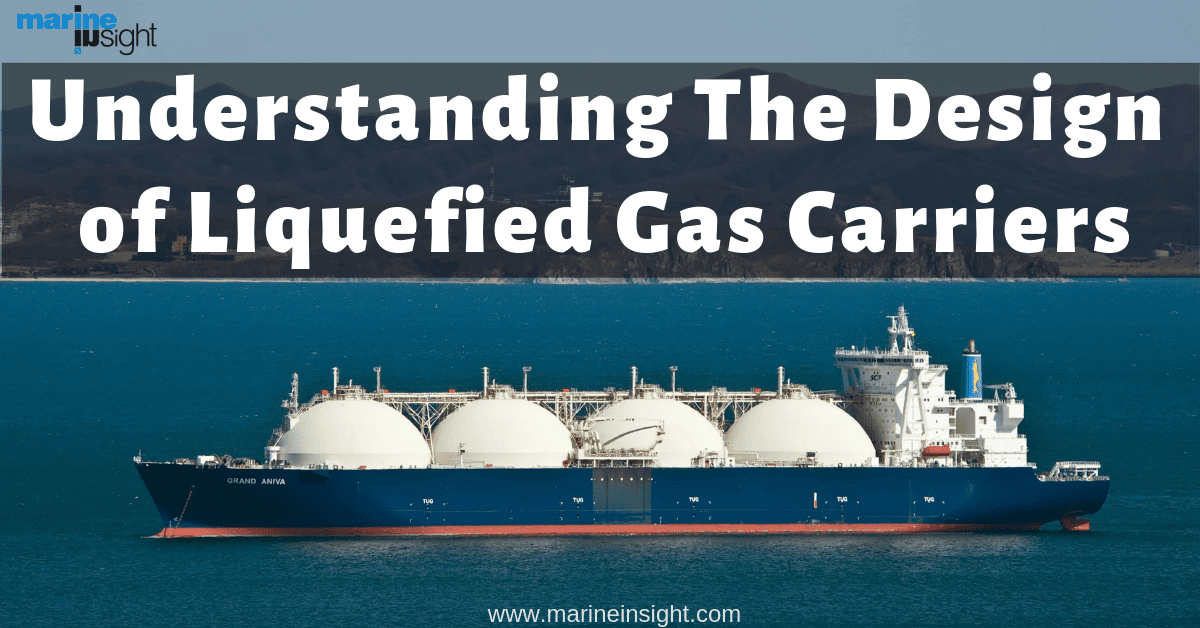

A large portion of the cng carrier s capital cost is the gas containment system and associated safety and gas control systems.

Natural gas containment systems. The inside of a moss type lng carrier. We engineer and manufacture the lightest and highest capacity cng tanks cng fuel systems for light medium and heavy duty trucks and virtual pipeline trailers vp650 for natural gas transportation. In the event that the tank integrity of a lng transport is compromised there is a risk that the natural gas contained within could ignite causing either an explosion or fire. Utah s intermountain power agency ipa which serves 21 municipal power utilities contracted mitsubishi hitachi power systems to build a gas turbine system to october 3 2020 markets.

The majority of lng carriers are between 125 000 and 135 000 m 3 4 400 000 and 4 800 000 cu ft in capacity. Dave wrightoctober 3 2018containment liners. Typical uses of rovanco containment pipe include oil natural gas chemicals solvents process waste gasoline and acid transfer lines. Oil and gas production is a highly regulated industry and rightly so.

The scope of the production facility depends on the quality of the gas and reservoir pressure but is a small fraction of that of a comparably sized lng or gtl facility. What are oilfield secondary containment requirements. This is the introduction of several smaller ships of between 18 000 and 19 000 m 3 640 000 and 670 000 cu ft having been built in 1994 and later to service the needs of importers of smaller. In the modern fleet of lng carriers there is an interesting exception concerning ship size.

Originally developed for oil and natural gas fields for economic containment purposes brock secondary containment systems are now widely used wherever containment is required. Oils spills such as the devastating exxon valdez oil spill in 1989 have been known to negatively impact drinking water cause public health crises and ravage natural resources and wildlife.